helical end mills feeds and speeds

Spindle Speed with Override. Machining Advisor Pro paired with Helical End Mills is the Holy Grail of End Mill Performance.

End Mills With Diameter 20 Mm For Milling Experiments A End Mill With Download Scientific Diagram

A bottoming tap has almost no taper at the end because it is designed to thread all the way to the bottom of its reach.

. When using clamps to secure a workpiece be sure that they are tight and that the piece is held so it will not spring or vibrate under cut. Machining Advisor Pro is a cutting edge resource for generating customized running parameters specifically for Helical Solutions end mills Machinist Blog - In The Loupe. Helical Metric Thread Milling Cutters.

Tapered Drill Reamer. Circular Interpolation or Helical Interpolation is something we see often in CNC programming. Its ideal for deburring complex shapes and.

Use good judgment and common sense in planning every job and profit from previous mistakes. Search the complete library of Speeds Feeds. Explore our 270 Deburring Undercut End Mill.

Spiral 3. Long Reach 90 Degree. The 2017 Conical Tool catalog featuring our line of high-speed steel and carbide end mills tapered end mills and specialty cutting tools.

These special Haas g-codes make it easy to perform the operation. Standard 2-3 flute end mills running at recommended speeds and feeds and proper chip loads can evacuate chips fairly well. The specially engineered end profile featured on Helicals High Feed End Mills works to minimize cutting forces while its reduced neck geometry provides maximum strength in long reach and deep pocketing applications.

The West Burton power stations are a pair of power stations on the River Trent near Gainsborough Lincolnshire EnglandWest Burton A is a coal-fired power station which was commissioned in 1966 and West Burton B is a combined cycle gas turbine power station commissioned in 2013. The screw operates at speeds of 100 to 200 rpm and vertically conveys incoming materials from the bottom generally the intake end like a screw conveyor to the top where they are scattered and fall by gravity. By selling directly to end users we provide the best quality products at.

As always our software is fully customizable for those who want to have full low-level control but Vectrics new Kickstarter wizard can also help you get started with a. 90 Degree with Tip Radius. Single Form Thread Milling Cutters.

30 45 60 90. Improve surface finish in all of your undercutting deburring and multi-axis machining applications with our Undercutting End Mills. Helical Solutions offers high balance tooling in standard 2 flute styles as well as coolant-through 3 flute styles for reduced heat enhanced chip evacuation and increased material removal rates.

Reduces the depth of cut and. Axial and Radial chip thinning. Is a national retail and internet company providing a wide variety of high-quality woodworking and metalworking machinery power tools hand tools and accessories.

Although a single-screw extruder provides a degree of end-to-end mixing the residence time of the melt is of the order of only 10 s. Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutterIn a milling machine the cutter is rotating due to workpiece is fed against itThis machine can hold more than one tool at a time. Set up every job as close to the.

Bottoming Taps are useful for threading blind holes. These tools like the. Speeds.

MAP is our go-to solution for High Efficiency Milling and has exponentially decreased our run times as well as increased our tooling life. The cutter rotates at high speed and because of the many cutting edges it removes metal at a very fast rate. On the other hand it is quite effective especially at high back pressure as a distributive mixer on a small scale thus forming a useful compounding device when fed with a blend containing masterbatch a premix or following an intensive high-speed.

The - buttons allow you to fine tune feeds in 5 increments while the program is in motion. This sequence is repeated several times until a blend is attained usually from 10 to 12 minutes. Machinist Blog - In The Loupe.

Request for quote and technical information is also available for download and we will be adding other materials as they become available. Balancing Depth Of Cut against Width Of Cut and vise-verse. 2 Flute TiCN.

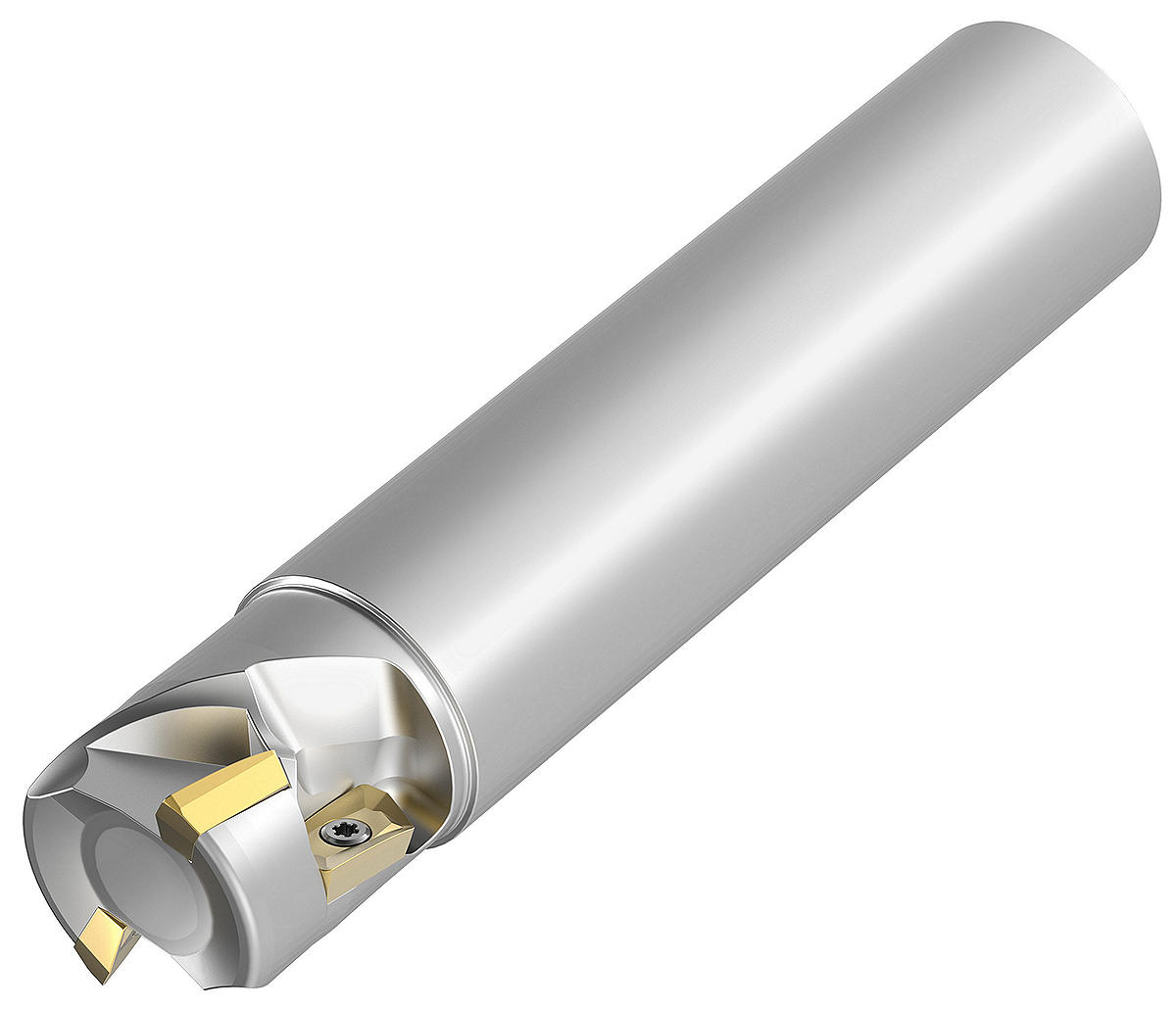

The processes that have this common theme are collectively called subtractive manufacturing in contrast to additive manufacturing which uses controlled addition of materialExactly what the controlled part of the definition implies can. No one has a larger selection of in stock items or the years of expertise to help you. These tools allow for drastically increased feed rates enabling maximized chip thickness and low radial forces when machining in steels up to 45 Rc.

Its desireable to thread most of the hole with a Taper Tap first and then finish the bottom of the hole with a Bottoming Tap. Composite High Feed Mills. All posted Speed Feed parameters are suggested starting values that may be increased given optimal setup conditions.

18 to 7 40 HP top head 30 HP bottom head 3500 RPM motors Feed Speed. Machining is a process in which a material often metal is cut to a desired final shape and size by a controlled material-removal process. Find the exact tool you need by searching tool style operation.

G12 cuts in a clockwise direction while G13 cuts counter-clockwise. 2 Flute Long Reach. 090 High-Speed Cutting Mills.

Whether you need to finish sharp corners contour mill with clearance machine draft angles add chamfers finish cavities or taper holes. These mixers may also be loaded from the top. PCD Diamond Ball End Mills.

V11 significantly improves the management of your CNC machine its capabilities for example rotary or laser add-ons associated post-processors and default tool cutting feeds and speeds for a selection of materials. Only 1 to 15 threads will be tapered. MLS Number 10822851 Baxter Whitney S970 Wood Planer Top and bottom planer with helical heads 36 width capacity Workpiece height.

Do not change feeds or speeds while the milling machine is in operation. Micro 100s Micro-QuikQuick Change Tooling Designed in our world class grinding facility in Meridian Idaho Micro 100s Micro-Quik product line is a breakthrough system that saves machinists countless hours without sacrificing performance. PCD Diamond Square End Mills.

West Burton A is owned and operated by EDF Energy while West. 33-98 FP Serial 18793 Electrical cabinet Grinding and sharpening attachments Removed from service November 2020. Optimal Depth Of Cut and Width Of Cut suggestion.

Fail-Safe Speeds and Feeds for Milling Drilling and Turning. The - buttons allow you to fine tune feeds in 5 increments while the program is in motion. Your Source for Machining Solutions including technical tips machining how-tos Find A Tool.

Use a recommended cutting oil liberally. Speeds FeedsAramid Core. Speeds and Feeds - The best feed and speed calculator on the market.

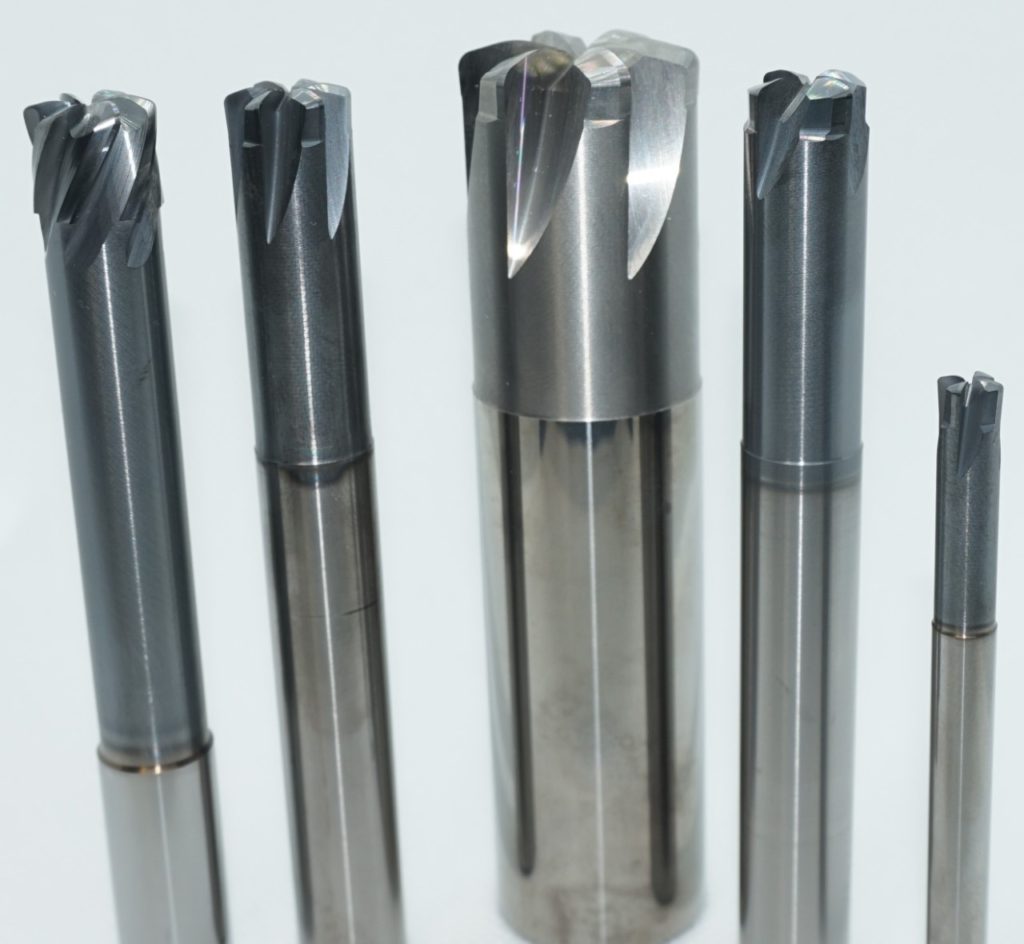

Your Source for Machining Solutions including technical tips machining how-tos Find A Tool. Our Conical Tapered Carbide end mills feature advanced variable geometries to reduce harmonics increase speeds and feeds and improve cycle times. High Performance Modular Solid Carbide End Mills DUO-λOCK General Purpose End Mills.

Plug Taps are in between Bottoming and. Find the exact tool you need by searching tool style operation or material and filtering by the precise dimensions. Results show that vertical.

You can adjust speeds using the slider from a slow minimum RPM to the max RPM according to the machine setup. Dagger Drill Carbide. Its a case where an endmill is programmed to follow a circular or helical path to make a much bigger hole than the diameter of the endmill.

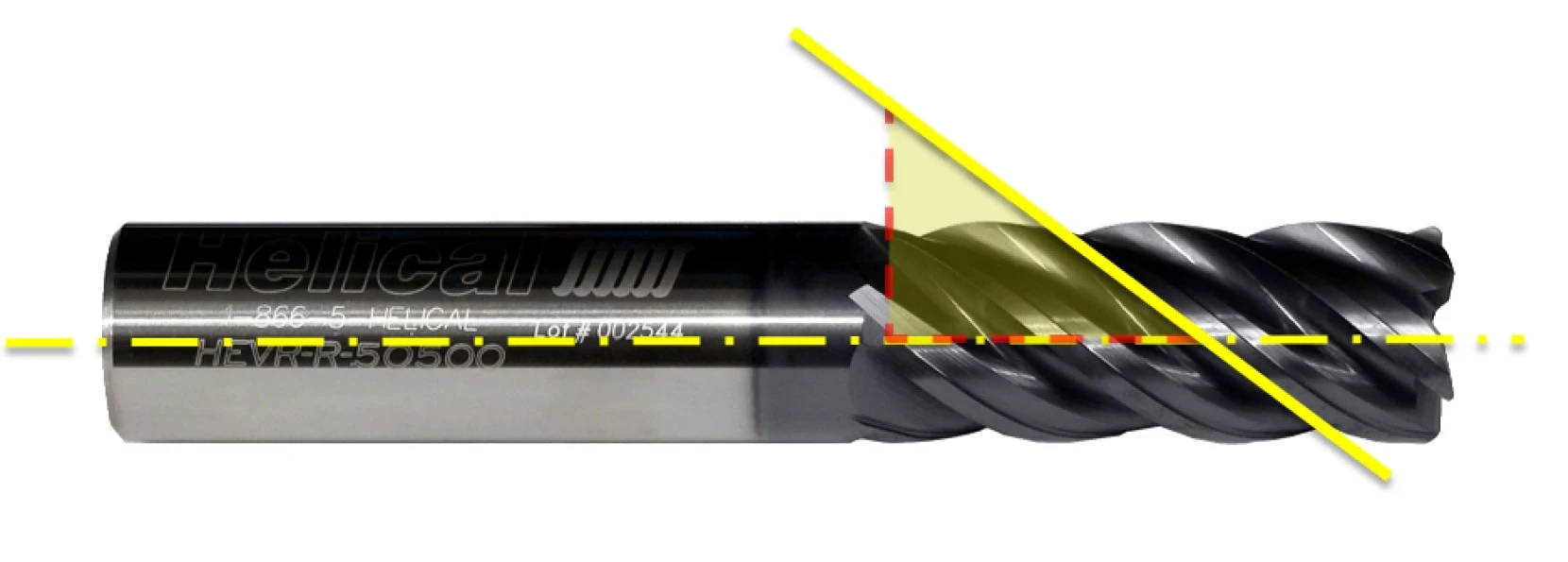

Specification Variable Helix End Mill

Stability Lobe Diagrams For Milling System With Different End Mills A Download Scientific Diagram

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

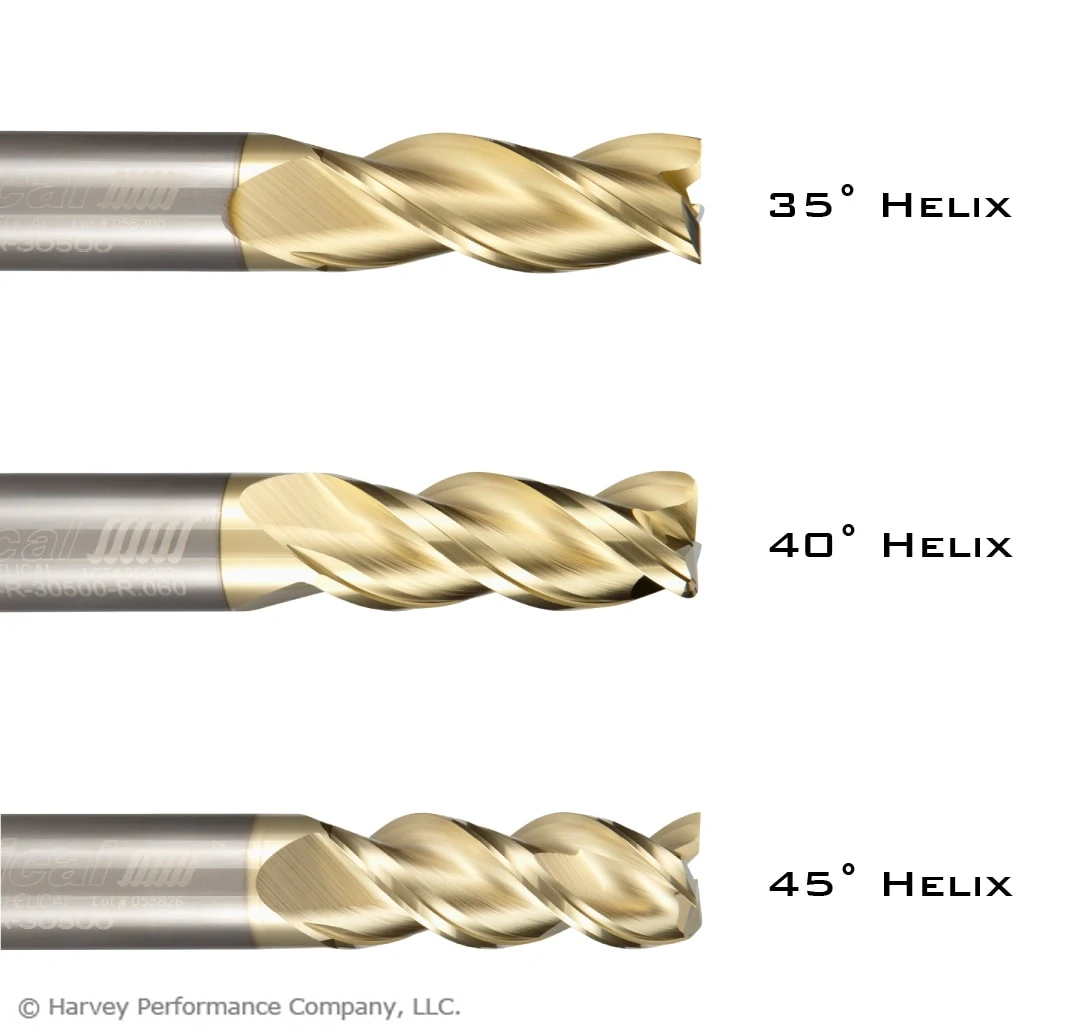

Helix Diameter Archives Harvey Performance Company

Carbide End Mill Carbide End Mills For 60hrc Exporter From Bahadurgarh

High Helix Carbide End Mill At Rs 3000 Unit Solid Carbide End Mills Id 20478637012

4 6 Flute High Feed End Mills Epic Tool

Basic End Mills Technical Information Msc Industrial Supply Co

End Mill Helix Angle Selection Blogs Www Cnctimes Com

Mill 1 10 Helical Indexable Helical End Mills

Basic End Mills Technical Information Msc Industrial Supply Co

Helix Diameter Archives Harvey Performance Company

End Mill An Overview Sciencedirect Topics

End Mills Contour360 High Performance End Mill Manufacturers

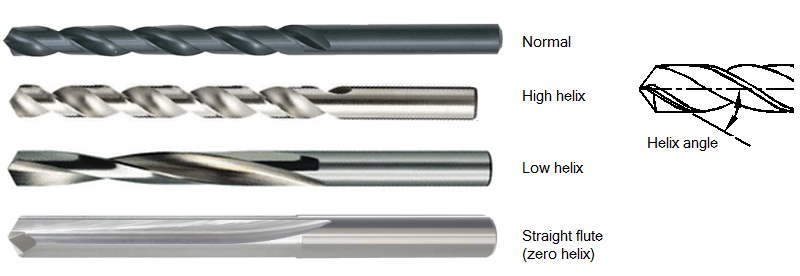

Helix Angle In Drill Where Each Angle Is Used Cadem

Technology Spotlight High Speed Trochoidal Tools

Series 6773 Inch Rf100 Speed 4 Fl Std Length End Mill Guhring